MIL-DTL-17361G(SH)

4.5.12.1.4.1 Pre-interruption. Temperature rise shall not exceed the requirements of molding and insulating

materials specified in MIL-E-917. Temperature rise shall not exceed 65 °C rise for terminals and slip type

connectors.

4.5.12.1.4.2 Post-interruption. Temperature rise shall not exceed 150 percent of the allowable values specified

in 4.5.12.1.4.1.

4.5.12.2 Attachments. Temperature rise of electric operating mechanism, undervoltage release device, shunt

trip, and auxiliary contacts shall be measured during electrical endurance testing while the attachments are used to

cycle the circuit breaker. Sensors shall be located on the housing of the electric operating mechanism, undervoltage

release device, and shunt trip to determine the temperature rise. For auxiliary contacts, a sensor shall be located on

insulation material nearest to the "a" contact used as the shunt trip cut-off switch. The temperature rise of

attachments shall not exceed the allowable temperature rise of the circuit breaker insulating material specified in

4.5.12.1.4.1.

4.5.13 Interrupting performance. Interrupting tests shall consist of AC or DC tests as applicable. The circuit

breaker under test shall be omitted from the test circuit or short circuited during the calibration of the test circuit.

Interrupting performance for 400-Hz circuit breakers shall be tested with a 60-Hz power source. Cheese cloth shall

be placed around the handle and at the terminals prior to testing.

4.5.13.1 Test circuit.

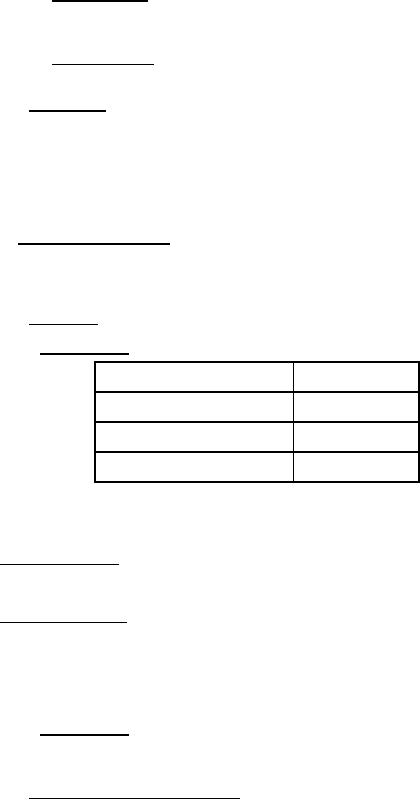

4.5.13.1.1 AC test circuit. Interrupting tests shall be made in a circuit having a lagging power factor as follows:

Nominal test circuit current

Power factor

010,000 amperes

0.450.50

10,00115,000 amperes

0.250.30

15,001above

0.150.20

The test circuit current shall be the total rms current including the DC component and shall be taken as the average

of all three phases. It shall be measured at 1/2 cycle after the short circuit occurs, and shall be calculated in

accordance with the following (refer also to ANSI/IEEE C37.09).

a. Symmetrical waves. Currents which are symmetrical about the zero axis have an rms value equal to the

peak-to-peak value divided by 2 √2. The peak-to-peak value at the desired instant shall be measured from the

envelope of the current wave.

b. Asymmetrical waves. These may be considered as composed of two components, an alternating and a

direct component. The alternating component has a peak-to-peak value equal to the distance between the envelopes

and has an axis midway between the envelopes. It shall be measured as for the symmetrical waves. The direct

component has an amplitude equal to the displacement of the axis of the alternating component. The total rms value

of an asymmetrical wave is equal to the square root of the sum of the squares of the symmetrical and direct

components taken at the desired instant.

4.5.13.1.2 DC test circuit. The current measured shall be the maximum value. The test circuit shall be adjusted

so that the initial rate of current rise shall not be greater than 10 amperes per microsecond with two poles connected

in series.

4.5.13.2 Test sequence and pass/fail criteria. At least three interrupting tests shall be made on each type circuit

breaker sample except for circuit breakers combined with fuses or current limiting fuse units. For fused circuit

breakers, refer to the applicable individual specification sheets (see 3.1) and 3.5.17.1. For circuit breakers combined

with fuse units, refer to the applicable individual specification sheets (see 3.1) and 3.5.17.2. Unit operations (see

6.4.31) shall consist of an "O" unit operation followed at a 5-minute interval by a "CO" unit operation followed at a

5-minute interval by a "CO" unit operation. After each interruption the circuit breaker reset time (see 6.4.24) shall

be recorded. The circuit breaker shall successfully interrupt during the entire sequence and cheese cloth placed

around the handle and at the terminals shall not be ignited. The circuit breaker shall be verified to be in operable

condition after the third interruption by manually cycling the circuit breaker.

33

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business