MIL-DTL-17361G(SH)

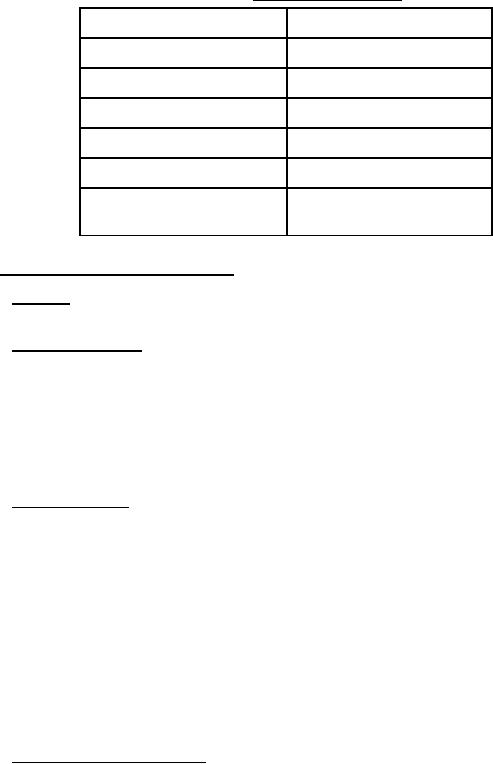

TABLE VII. Conformance inspection.

Unit

Inspection

Circuit breaker frame

4.5.1, 4.5.4

Mounting blocks or base

4.5.1, 4.5.4

Trip unit

4.5.1, 4.5.4, 4.5.10

Fuses (if applicable)

4.5.1

Fuse unit (if applicable)

4.5.1

Attachments

3.5.19.6, 4.5.1, 4.5.4, and

Tables II, III, and IV

4.4.3 Conformance production shock testing.

4.4.3.1 Sampling. One circuit breaker shall be selected at random by a Government representative for each

frame type produced during a month regardless of feature or attachment and subjected to the production shock test.

4.4.3.2 Production shock test. The shock tests shall be conducted on the sample circuit breakers and

attachments. The shock tests of 4.5.14 apply except as modified by the following:

a.

The circuit breaker shall be tested in the closed position.

b.

No load is necessary except as required for the undervoltage release device.

c. The circuit breaker shall be subjected to one hammer blow of 3-foot drop from each direction top, back,

and side.

d.

No adjustment to the circuit breaker is permitted before or during the shock test.

4.4.3.3 Acceptance criteria. The circuit breaker will be acceptable if the following criteria have been met:

a.

The circuit breaker shall remain closed during and following the test.

b. The circuit breaker shall be turned off and then on after each hammer blow to verify that the mechanism has

not jammed to the extent that it could not trip open.

c. The circuit breaker shall pass an electrical calibration test (both LTD and instantaneous) following the

shock test. For electronic trip unit type circuit breakers, actual trip values after the test shall be within specified

limits (see 3.1). For thermal magnetic trip unit type circuit breakers, actual trip values after the test shall be ±15

percent of the pre-shock calibration and the circuit breaker trip unit shall have the ability to be readjusted to

specified limits (see 3.1).

d.

The circuit breaker shall pass the dielectric test following the shock test.

e. Proper undervoltage or shunt trip device operation should be verified following the shock test if an

undervoltage or shunt trip device is installed.

4.4.3.4 Action required if failure occurs. In cases where the selected circuit breaker does not meet the

acceptance criteria, it shall be analyzed to determine the cause of the failure. The following procedure shall be

followed:

a. If the cause can be identified, all circuit breakers of the same frame type shall be reworked and shipment of

these shall be suspended until corrective actions have been completed, as specified (see 6.2). After the circuit

breakers have been reworked, a sample randomly selected by a Government representative shall be production shock

tested to assure that the corrective action is effective. In case further reworking of the circuit breaker is necessary, a

sample shall be randomly selected by a Government representative from the reworked lot and subjected to

production shock test to assure corrective action is effective.

21

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business