MIL-DTL-17361G(SH)

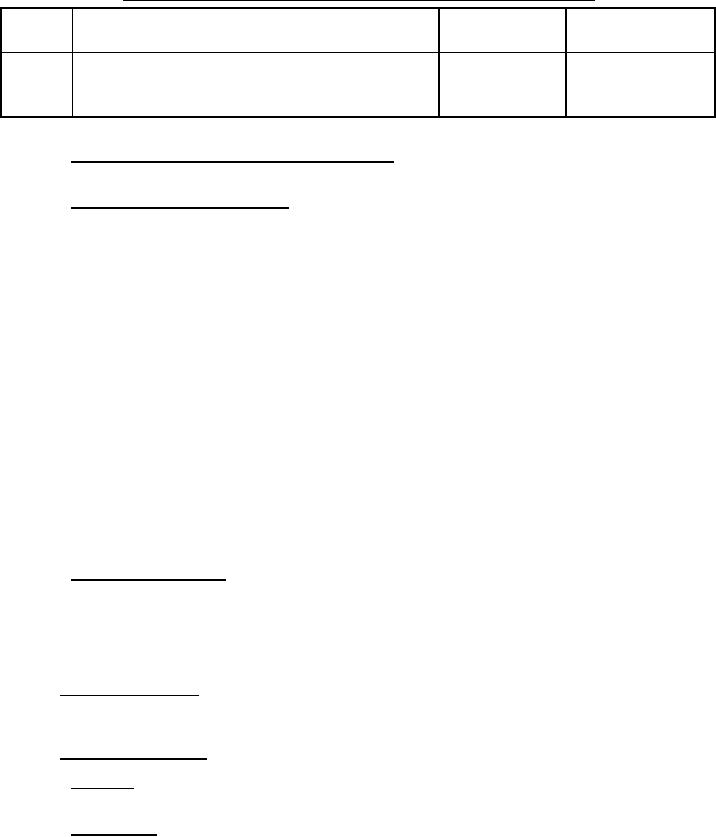

TABLE VI. Qualification inspection test schedule (for inspection samples 1B, 2B, and 3B) - Continued.

Test

Inspection

Requirement

Verification

number

17

Insulation resistance (1-megohm threshold)

3.4.2

4.5.5

3.5.14.3

3.5.18.1

4.2.2 Qualification inspection of type NQB circuit breakers. Satisfactory tests performed on an associated

Type AQB circuit breaker frame shall be extended to cover the Type NQB circuit breaker.

4.2.3 Samples for qualification inspection. Tests shall be conducted on a sample unit of both the maximum and

minimum trip unit rating of each circuit breaker to be qualified. Samples shall include all available attachments (see

4.5.13.2 for samples required for additional interrupting tests). If a sample cannot contain all available attachments,

an additional sample shall be provided to accommodate the attachments not permissible in the first sample. Test

samples are required as applicable in the following categories:

Sample 1A

-

One 3-pole AC, 60-Hz circuit breaker of maximum trip unit rating.

1B

-

One 3-pole AC, 60-Hz circuit breaker of minimum trip unit rating and, if applicable,

communications capabilities installed.

2A

-

One 3-pole AC, 400-Hz circuit breaker of maximum trip unit rating.

2B

-

One 3-pole AC, 400-Hz circuit breaker of minimum trip unit rating and, if applicable,

communications capabilities installed.

3A

-

One 3-pole DC, circuit breaker of maximum trip unit rating.

3B

-

One 3-pole DC, circuit breaker of minimum trip unit rating and, if applicable,

communications capabilities installed.

Sample types 1A, 2A, and 3A shall be used for the entire test sequence of Table V and sample types 1B, 2B, and 3B

shall be used for the entire test sequence of Table VI.

4.2.4 Retention of qualification. At a maximum of three year intervals after qualification, the manufacturer

shall provide production line circuit breaker and mounting base test samples with attachments/fuses/fuse units (as

applicable) and conduct a comparison inspection (see 4.3). At a maximum of six year intervals, a qualification

inspection (see 4.2 through 4.2.3) shall be conducted on production line circuit breaker and mounting base test

samples with attachments/fuses/fuse units (as applicable). A qualification inspection may be conducted in lieu of a

comparison inspection at the three-year interval. Test reports shall be submitted as specified (see 6.2).

4.3 Comparison inspection. For comparison inspection tests, a circuit breaker sample of each 1A, 2A, and 3A

shall be tested. The test shall be in compliance with test numbers 1, 2, 4, 5, 6, 8, and 9 of Table V and test numbers

3 and 4 of Table VI.

4.4 Conformance inspection.

4.4.1 Inspection. Each manufactured unit shall be subjected to the inspection specified in Table VII, unless

inspection sampling is otherwise specified (see 6.2).

4.4.2 Rejected units. If a unit is rejected, the contractor shall rework the unit to correct the defects and

resubmit the unit for inspection, as specified (see 6.2). Such units shall be separate from new units and shall be

clearly identified as a resubmitted unit for inspection. The contractor shall also determine if the identified defect is

likely to exist in other in-process and completed units, and inspect and disposition these units if appropriate.

20

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business